5 Best Tips For Customizing A Car

As an experienced car mechanic, and someone who customizes cars for a living, I can attest that tricking out a car is not a simple process. If you are not careful, car customization projects can be fraught with unseen expenses, quality issues, and delays. Experienced plays a big part in mitigating these issues, but more than anything, adhering to a process and plan will save you and your customizer valuable time , money, and headaches.

So today I wanted to share the simple 5 step process I use with every job, regardless of the size or budget. So let’s begin with a plan…

1. Start With A Goal In Mind

Cars, just like people, can be finicky. That’s why it’s absolutely necessary to clearly spell out what the vehicle will look like, and how it will function at the end of the process.

The less wiggle room the better.

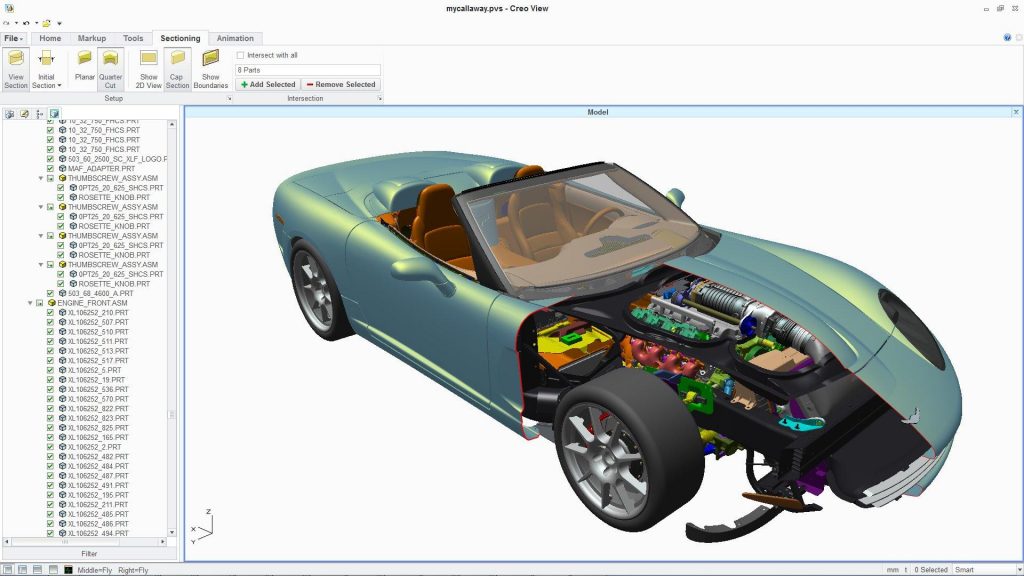

That means extremely detailed concept drawings, and concept descriptions. If you’re a gifted sketch artist that’s great, but I’m not, and I need the help of modeling software to get the job done. For our purposes, we use ProEngineer (now Creo). While expensive, this parametric modeling software allows you do to fatigue analysis as well as specify the material used for production – which is great for communicating to our suppliers if custom parts are required.

There’s even a light-weight version that we use to communicated to our clients for concept agreements online.

For less expensive alternatives, we recommend a product called Solidworks which operates essentially the same way. Here’s a discussion on the merits of each.

2. Think In Terms Of Budget

Carefully think about your budget. That means itemizing every expense you’ve come up with in the concept stage. Even though I consider myself a good mechanic, I haven’t had a single project that’s gone EXACTLY according to plan. So make sure that any budget includes stipulations for overtime and rework.

3. Find Reliable People

In our business, a good mechanic is worth his or her weight in gold. I run the business end of the operation, and while I can customize the shit out of anything, the business needs to be run like a boss.

So to make our business hum, we employ the very best project managers, mechanics, and metal workers to handle the production process. Finding good people takes time and resources, but it’s well worth it. The key, as in most things in life, is paying that person what they’re worth, and treating them well, with clear expectations of what their jobs and responsibilities entail.

4. Prioritize Investments

Making rash decisions with your money will never get you anywhere. Prioritize the investments and make sure that you consult your decision with your project teams.

Then you will be able to pick the investments in your car customization that will give the best results.

5. Plan For the Unexpected

For the final step in the process, I always circle back with my team to discuss contingencies. That means really thinking about any and all steps and understanding how it could go off the rails. We also make sure that the customer agreements are airtight, and that the timelines proposed will fit into the workload of the project team moving forward.

This step helps us squeeze the most out of every project. Will you or the customer be selling the car? Do you just want to have a certain type of car that looks a certain way? Plan ahead and think what will give you the most joy or bring the most profit.